Loading Systems

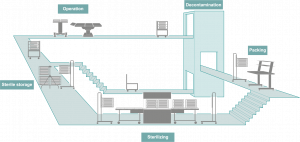

A higher level of quality and efficiency create higher demands on medical personnel and equipment. In spite of new technology, some work still overwhelms today ́s medical personnel. Remeda’s products provide simpler and more effective solutions for work in operating departments and central sterilization departments.

The Remeda loading systems have been developed in order to create a more effective handling of goods at the hospital, without creating strain on the personnel. Remeda has a large variety of different loading and transport solutions. From manual loading systems using fixed height trolleys and racks or basket feeders to multi loading systems where the Multiloader loads a line of sterilizers from one or several conveyors.

| Reference number | Sterilizer chamber dept mm (inch) | Type of load |

|---|---|---|

| 100 41-00 | 600-700 (23,6-27,6) | Basket |

| 100 41-01 | 900-1000 (35,4-39,4) | Basket |

| 100 41-02 | 1200-1300 (47,2-51,2) | Basket |

| 100 41-03 | 1600-1700 (63,0-66,9) | Basket |

| 100 41-04 | 1900-2000 (74,8-78,7) | Basket |

| 100 41-10 | 600-700 (23,6-27,6) | Rack |

| 100 41-11 | 900-1000 (35,4-39,4) | Rack |

| 100 41-12 | 1200-1300 (47,2-51,2) | Rack |

| 100 41-13 | 1600-1700 (63,0-66,9) | Rack |

| 100 41-14 | 1900-2000 (74,8-78,7) | Rack |

The Remeda floor loader is designed for loading and unloading floor and pit mounted sterilizers.

There are several different versions of floor loaders, depending on which type of sterilizers and loading transport trolleys that are used and the installation of the sterilizers.

The loader is designed to load or unload larger racks on wheels and will be built to fit the standard racks already in use at the central sterilization department.

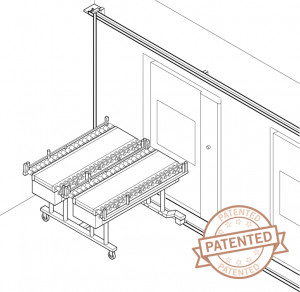

Dual Loader

The Remeda Dual loader is designed for loading/unloading baskets or racks on single door sterilizers.

The Dual loader has one loading and one unloading side. The Dual loader is also available in a Multi loader version for single door sterilizers. The control of the loader communicate with the control of the sterilizer.

Remeda has a wide range of loading and transport trolleys optimised for use with the Dual loader.

The Remeda Multi loader is a fully automated system which uses single point loading and unloading of baskets or racks. It is designed to minimize the personnels handling of the goods and can work in a closed working environment without the need of supervison.

The Multi loader’s shuttle collect goods from one or several conveyors and load it into the sterilizer when it is available.

The integrated control system control the number of cycles of each sterilizer and select the sterilizer with the least amount of cycles. This is done to make sure that all the sterilizers are used the same amount.

The control of the loader communicate with the control of the sterilizer.

The Remeda Multi loader is suited for sterilization department where there is a space restriction or when the sterilisers are situated in a closed space.

Different combination with multi loading and automatic unloading can be done. Remeda has a wide range of loading and transport trolley´s optimised for use with the Multi loader.

200 52 Transport Trolley

The Remeda transport trolley is used together with the automatic loader on conveyors in the central sterilization department. The height of the trolley can be adjusted so that loading and unloading can be carried out at suitable working height. Thanks to the unique lifting system, the trolley is exceptionally easy to clean. The height adjustment is electric and controlled by an easy operated control placed on the handle. The trolley is delivered with a charger for the battery. The handle is mounted on the bottom part of the trolley, and stays at normal height. The top of the trolley is designed for transportation of baskets and racks without wheels. The trolley is manufactured in stainless steel with a frame in stainless steel profile piping. Equipped with four castors with diameter 125mm, of which 2 with brakes and 2 with direction locking. The trolley is available in a fixed height version as well.

| Reference number |

Height adjustment mm |

Capacity, baskets |

|---|---|---|

| 200 52-01 | 585-885 | 4 DIN |

| 200 52-11 | 600-950 | 4 DIN |

| 200 52-21 | 600-950 | 4 DIN |

| 200 53-02 | 585-885 | 6 ISO or 6 SPRI |

| 200 53-12 | 600-950 | 6 ISO or 6 SPRI |

| 200 53-22 | 600-950 | 6 ISO or 6 SPRI |

| 200 52-02 | 585-885 | 6 DIN |

| 200 52-12 | 600-950 | 6 DIN |

| 200 52-22 | 600-950 | 6 DIN |

| 200 52-03 | 585-885 | 8 DIN or 9 ISO or 9 SPRI |

| 200 52-13 | 600-950 | 8 DIN or 9 ISO or 9 SPRI |

| 200 52-23 | 600-950 | 8 DIN or 9 ISO or 9 SPRI |

| 201 52-01 | 800-900 | 4 DIN |

| 201 52-11 | 900-1000 | 4 DIN |

| 201 52-02 | 800-900 | 6 DIN |

| 201 52-12 | 900-1000 | 6 DIN |

| 201 52-03 | 800-900 | 8 DIN or 9 ISO or 9 SPRI |

| 201 52-13 | 900-1000 | 8 DIN or 9 ISO or 9 SPRI |

| Ref. no. | Fixed height mm | Chamber dept mm |

|---|---|---|

| 201 80-01 | 800-900 | 600-700 |

| 201 80-11 | 900-1000 | 600-700 |

| 201 80-02 | 800-900 | 900-1000 |

| 201 80-12 | 900-1000 | 900-1000 |

| 201 80-03 | 800-900 | 1200-1300 |

| 201 80-13 | 900-1000 | 1200-1300 |

| 201 80-04 | 800-900 | 1600-1700 |

| 201 80-14 | 900-1000 | 1600-1700 |

| Ref. no. | Height adj mm | Chamber dept mm |

|---|---|---|

| 200 80-01 | 560-860 | 600-700 |

| 200 80-11 | 610-960 | 600-700 |

| 200 80-21 | 660-1060 | 600-700 |

| 200 80-02 | 560-860 | 900-1000 |

| 200 80-12 | 610-960 | 900-1000 |

| 200 80-22 | 660-1060 | 900-1000 |

| 200 80-03 | 560-860 | 1200-1300 |

| 200 80-13 | 610-960 | 1200-1300 |

| 200 80-23 | 660-1060 | 1200-1300 |

| 200 80-04 | 560-860 | 1600-1700 |

| 200 80-14 | 610-960 | 1600-1700 |

| 200 80-24 | 660-1060 | 1600-1700 |

The Remeda Semi Automatic Loading (SAL) trolley is designed to load and unload the sterilizers chamber which a push of a button. On top of the trolley can be placed either a shelf rack or a transfer platform depending on what kind of goods it is supposed to handle. The height of the trolley can be adjusted so that loading and unloading can be carried out at suitable working height. Thanks to the unique lifting system, the trolley is exceptionally easy to clean. The height adjustment is electric and controlled by an easy operated control placed on the handle. The handle is mounted on the bottom part of the trolley, and stays at normal height during operation. The top is equipped with a guiding and locking system, to lock the trolley to the autoclave chamber rails. The trolley is manufactured in stainless steel with a frame in stainless steel profile piping. Equipped with four castors with diameter 125mm, of which 2 with brakes and 2 with direction locking. The trolley is designed for autoclaves with square chamber opening width of about 660-700mm. The trolley is available in a fixed height version as well.

| Ref. no. | Height adj mm | Chamber dept mm |

|---|---|---|

| 200 80-02-SAL | 550-850 | 900-1000 |

| 200 80-12-SAL | 600-950 | 900-1000 |

| 200 80-03-SAL | 550-850 | 1200-1300 |

| 200 80-13-SAL | 600-950 | 1200-1300 |

| 200 80-04-SAL | 550-850 | 1600-1700 |

| 200 80-14-SAL | 600-950 | 1600-1700 |

200 88 Loading Trolley

The Remeda loading trolley is designed to load and unload sterilizers in the sterilization and operating departments. The trolley is used together with a transfer platform that is rolled into the chamber. The platform rest on the chamber floor.

The height of the trolley can be adjusted so that loading/ unloading can be carried out at suitable working height. Thanks to the unique lifting system, the trolley is exceptionally easy to clean. The height adjustment is electric and controlled by an easy operated control placed on the handle. The trolley is delivered with a charger cable for the battery. The handle is mounted on the top part of the trolley. The trolley is manufactured in stainless steel with a frame in stainless steel profile piping. Equipped with four castors with diameter 100mm, of which 2 with brakes and 2 with direction locking.

The trolley is designed for autoclaves with square chamber opening width of 460mm. The loading height to be specified on order.

| Reference number |

Height adj. mm (inch) |

Chamber dept mm (inch) |

Platform |

|---|---|---|---|

| 100 88-01 | 570-870 (22,4-34,3) | 660 (26,0) | 100 88-21 |

| 100 88-02 | 550-850 (21,7-33,5) | 960 (37,8) | 100 88-22 |

| 100 88-11 | 600-950 (23,6-37,4) | 660 (26,0) | 100 88-21 |

| 100 88-12 | 600-950 (23,6-37,4) | 960 (37,8) | 100 88-22 |

| Reference number | Chamber dept mm (inch) | For chamber rail |

|---|---|---|

| 100 61-01 | 600-700 (23,6-27,6) | 100 61-51 |

| 100 61-02 | 900-1000 (35,4-39,4) | 100 61-52 |

| 100 61-03 | 1200-1300 (47,2-51,2) | 100 61-53 |

| 100 61-04 | 1600-1700 (63,0-66,9) | 100 61-54 |

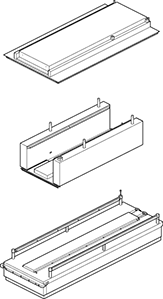

200 64 / 200 65 Transfer Platform

The Remeda transfer platform is used together with a trolley or automatic loader to carry the goods through the sterilizers.

The transfer platform allows goods to be pre-loaded at the packing table and is manufactured in stainless steel, where baskets, containers or packs can be placed. The transfer platform is used in a circulating flow, and is returned to the clean, loading side after the sterilization process.

| Reference number |

Length mm (inch) | Width mm (inch) | For trolley type |

|---|---|---|---|

| 200 64-11 | 630 (24,8) | 608 (23,9) | 200 80 |

| 200 64-12 | 930 (36,6) | 608 (23,9) | 200 80 |

| 200 64-13 | 1260 (49,6) | 608 (23,9) | 200 80 |

| 200 65-11 | 630 (24,8) | 608 (23,9) | 200 52 |

| 200 65-12 | 930 (36,6) | 608 (23,9) | 200 52 |

| 200 65-13 | 1260 (49,6) | 608 (23,9) | 200 52 |

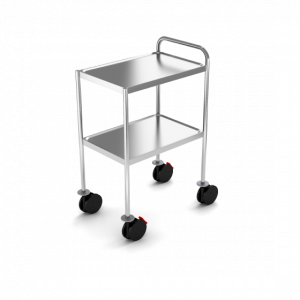

The transfer trolley is designed to facilitate the handling of goods within the central sterilization department. It allows personnel to easily transport items throughout the workspace, improving efficiency during daily operations.

| Reference number |

Table top mm (inch) |

Height mm (inch) |

Description |

|---|---|---|---|

| H19757 | 600×400 (23,6×15,7) | 800 (31,5) | Fixed height |

| H12985 | 600×400 (23,6×15,7) | 900 (35,4) | Fixed height |

| H37777 | 1070×570 (42,1×22,4) | 900 (35,4) | Fixed height |

The transfer trolley is designed for efficient handling of goods within the central sterilization department. Featuring electric height adjustment, it allows personnel to easily transport items and position them at the ideal working and lifting height. This enhances ergonomics, reduces physical strain, and supports a smoother workflow throughout the department.

| Reference number | Tabletop mm (inch) | Height mm (inch) | Capacity kg/lbs | Description |

|---|---|---|---|---|

| 10005-01 | 600×400 (23,6×15,7) | 650-1450 (25,5-57,1) |

15/33 | Height adjustable |

| 10005-02 | 700×500 (27,6×19,7) | 650-1450 (25,5-57,1) |

15/33 | Height adjustable |

| 10005-03 | 800×600 (31,5×23,6) | 650-1450 (255-57,1) |

15/33 | Height adjustable |

Pass Through Hatch

The Remeda Pass through hatch is crafted from durable stainless steel and fitted with glass doors. The pass through hatch ensures safe and efficient transfer of goods between sterile and clean areas. Its electrically operated doors open one at a time, minimizing cross-contamination and streamlining the movement of loading cars.

Designed for flexibility, the pass through hatch can be customized to integrate with automatic loading systems and conveyors. Its height can be adjusted to accomodate various loading equipment heights, enhancing compatibility across your workflow.

Available in multiple sizes, it supports both large sterilizer loading cars and smaller racks for washer disinfectors. The robust stainless steel backplate on the door frame ensures a tight seal against the wall, effectively minimizing airflow and maintaining environmental integrity.

Packbord

| Ref. nr | Bordsskiva stl. mm | Höjdreglering mm | Beskrivning |

|---|---|---|---|

| 100 10-21 | 1400×750 | 755-1255 | Höj- och sänkbar |

| 100 10-22 | 1600×750 | 755-1255 | Höj- och sänkbar |

| 100 10-23 | 1800×750 | 755-1255 | Höj- och sänkbar |

| 100 10-24 | 2000×750 | 755-1255 | Höj- och sänkbar |

| Ref. nr | Bordsskiva stl. mm | Höjdreglering mm | Beskrivning |

|---|---|---|---|

| 100 10-31 | 1400×750 | 755-1255 | Höj- och sänkbar |

| 100 10-32 | 1600×750 | 755-1255 | Höj- och sänkbar |

| 100 10-33 | 1800×750 | 755-1255 | Höj- och sänkbar |

| 100 10-34 | 2000×750 | 755-1255 | Höj- och sänkbar |